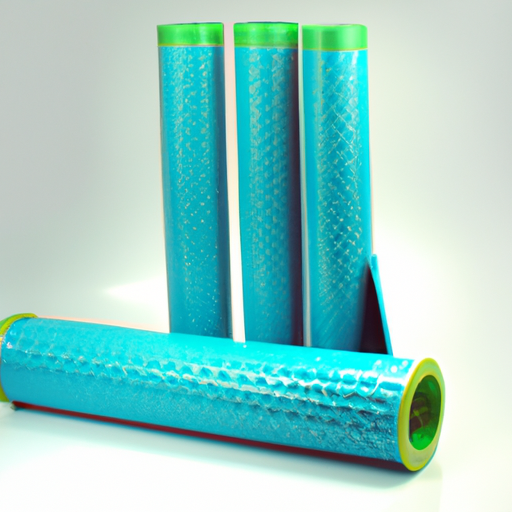

Application Development in Expandable Sleeve for SB-SGS-40 4.0KV Silicone Fiberglass Sleeving: Key Technologies and Success Stories

The development of applications for expandable sleeves, particularly the SB-SGS-40 4.0KV silicone fiberglass sleeving, is a multifaceted process that leverages advanced materials, innovative manufacturing techniques, and rigorous testing protocols. These sleeves are essential in providing electrical insulation, environmental protection, and mechanical support across various industries, including automotive, aerospace, and electronics. Below, we explore the key technologies involved and highlight notable success stories that demonstrate the effectiveness of these sleeves.

Key Technologies

| 1. Material Composition | |

| 2. Manufacturing Techniques | |

| 3. Testing and Certification | |

| 4. Application Development | |

| 1. Aerospace Industry | |

| 2. Automotive Applications | |

| 3. Consumer Electronics | |

| 4. Industrial Equipment |

Success Stories

Conclusion

The development of applications for expandable sleeves like the SB-SGS-40 4.0KV silicone fiberglass sleeving underscores the significance of material science, innovative manufacturing techniques, and rigorous testing. The success stories across various industries illustrate the versatility and effectiveness of these sleeves in enhancing safety, reliability, and performance in demanding environments. As technology continues to advance, further innovations in materials and application methods are expected to emerge, broadening the potential uses of silicone fiberglass sleeving and reinforcing its critical role in modern engineering solutions.